Bourbon whiskey is a quintessential American spirit with a deep-rooted history and a distinct, rich flavor profile. What many might not realize is the intricate process that goes into creating this beloved drink, from the grains in the field to the final sip in your glass. In this blog, we’ll explore the journey of bourbon whiskey, revealing the steps that transform raw ingredients into a smooth, full-bodied drink.

1. The Ingredients: Grains at the Core

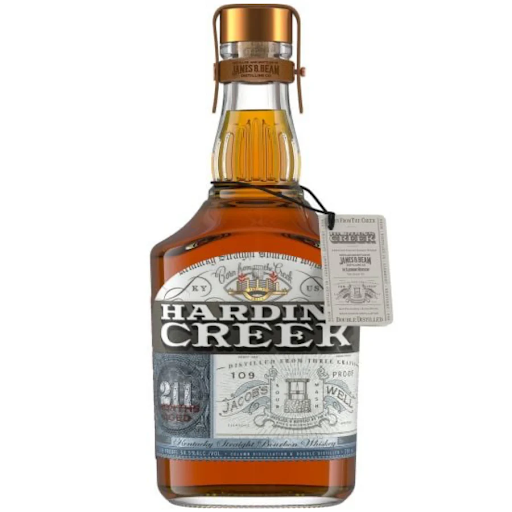

At the heart of every bourbon whiskey is its grain mix. The production of bourbon is tightly regulated by law, ensuring its authenticity and quality. By definition, bourbon whiskey must be made from a mash bill that contains at least 51% corn, which gives it its signature sweet flavor. The remaining percentage typically includes a mix of rye, barley, and sometimes wheat.

- Corn: The dominant grain in bourbon, corn provides the sweetness that characterizes the spirit.

- Rye: Often used for a spicier edge, rye adds complexity and depth to the whiskey.

- Barley: This grain is crucial for fermentation, as it provides enzymes that break down starches into fermentable sugars.

- Wheat: Some bourbon distillers use wheat to create a smoother, softer taste profile.

The balance of these grains is what gives each bourbon whiskey its unique flavor characteristics, and master distillers are often known for their proprietary recipes.

2. Mashing: The First Step in the Transformation

Once the grains are carefully selected, the next step is mashing. The grains are ground into a coarse powder and mixed with water, then heated to convert the starches in the grains into fermentable sugars. This process creates a thick, porridge-like mixture called “mash.” The temperature and time spent during this stage play a critical role in developing the final flavor profile of the bourbon whiskey.

At this point, enzymes from malted barley break down the starches into simpler sugars, allowing yeast to ferment them into alcohol. The mash is then transferred to fermentation tanks, where yeast is added to kickstart this fermentation process.

3. Fermentation: Turning Sugar into Alcohol

Fermentation is the next crucial stage in bourbon production. The mash is allowed to ferment for several days, during which the yeast consumes the sugars in the mash and produces alcohol. This results in a “beer-like” liquid, known as “wash,” which has an alcohol content of around 6-8%.

During fermentation, the yeast also produces flavors and aromatic compounds that contribute to the final taste of the bourbon whiskey. While fermentation is a natural process, it requires precise control to ensure the desired flavors are developed and the alcohol content is appropriate for distillation.

4. Distillation: Separating the Good from the Bad

After fermentation, the wash is ready for distillation. This process is crucial for concentrating the alcohol and separating undesirable components, such as fusel oils, which can cause off-flavors. Distillation takes place in copper pot stills or column stills, which heat the wash to vaporize the alcohol, then condense it back into liquid form.

The distilled liquid is called “white dog” and typically contains 60-80% alcohol by volume (ABV). It is now ready to undergo the aging process, where it will develop the rich flavors that make bourbon whiskey so distinct.

5. Aging: The Magic of Time

Bourbon whiskey must be aged in new, charred oak barrels, a step that plays a vital role in its flavor profile. The charring of the wood caramelizes the sugars inside the barrel, which imparts rich vanilla, caramel, and smokey flavors to the whiskey. The aging process also allows the whiskey to undergo chemical reactions that mellow the alcohol and create its signature smooth texture.

By law, bourbon must be aged for at least two years to be classified as straight bourbon, though many premium bourbons are aged much longer. The climate in which the bourbon is aged also affects its development, with distilleries in Kentucky being particularly famous for their aging conditions due to the state’s weather fluctuations.

Conclusion

From grain to glass, making bourbon whiskey is a meticulous, time-honored process that combines science, artistry, and tradition. Each stage, from the careful selection of grains to the aging process, contributes to the final product that delights whiskey drinkers around the world. While bourbon whiskey has its unique production methods and flavors, other spirits like Blanco tequila also offer distinct experiences. Both drinks showcase the depth of craftsmanship involved in spirit-making, whether it’s the rich, sweet notes of bourbon or the vibrant, fresh taste of Blanco tequila.