Aluminum extrusion is a process widely used in manufacturing, particularly in industries that require precision and strength in their products. Whether it’s for construction materials, automotive parts, or even consumer electronics, the aluminum extrusion process demands careful attention to the design of the die. The die plays a pivotal role in determining the quality, consistency, and cost-effectiveness of the finished product. But what makes an aluminum extrusion die design truly high-performance? In this article, we’ll explore the essential components and features that contribute to a high-performance aluminum extrusion die design.

The Importance of Die Design in Aluminum Extrusion

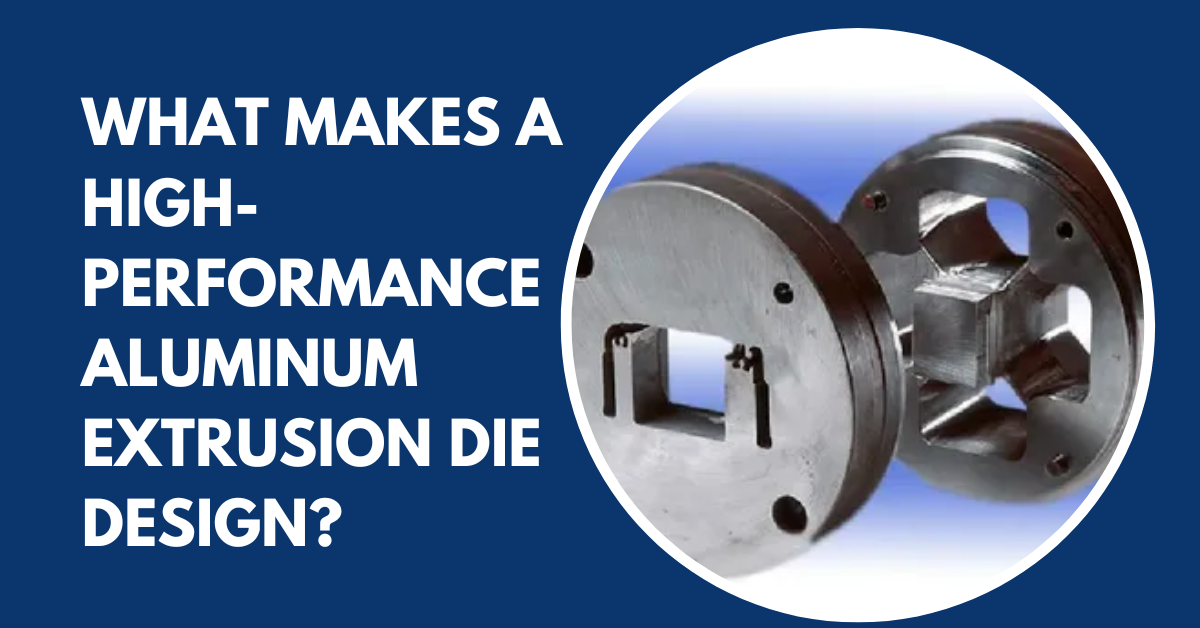

Before diving into the specifics of high-performance die design, it’s crucial to understand the role of the die in the extrusion process. The die acts as the mold through which the aluminum material is forced under high pressure to shape it into the desired form. It determines the final dimensions, surface finish, and even the mechanical properties of the aluminum product.

For manufacturers looking to optimize their extrusion process, the die design must be carefully considered. A poorly designed die can lead to defects like warping, uneven thickness, surface blemishes, and poor material flow. On the other hand, a well-designed die ensures smooth material flow, precise shaping, and higher overall efficiency in the production process. In this context, high-performance aluminum extrusion die design not only ensures the quality of the product but also impacts the efficiency, cost-effectiveness, and speed of the extrusion process.

Note – For businesses looking to enhance their manufacturing processes, investing in advanced Aluminum Extrusion Die Design is crucial for achieving optimal results. DDSPLM offers expert software solutions that can streamline your die design process, ensuring higher precision, reduced costs, and improved production efficiency. Explore how cutting-edge software can transform your aluminum extrusion operations and drive long-term success. Get in touch today to learn more about the innovative solutions available to optimize your die designs.

Key Factors That Make a Die Design High-Performance

High-performance aluminum extrusion die design is a complex combination of several elements that work together to ensure optimal results. Let’s take a closer look at the key factors that contribute to an effective die design.

1. Material Flow Optimization

One of the most critical aspects of die design is ensuring proper material flow. The goal is to allow the aluminum to flow smoothly and evenly through the die cavity to achieve the desired shape. The die should be designed in such a way that it minimizes the chances of material getting stuck or causing pressure imbalances.

In a high-performance die, the material flow should be uniform, and the aluminum should fill the die cavity completely without any voids or inconsistencies. This can be achieved by designing the die with appropriate channel dimensions, using tapered or radiused sections to guide the material, and ensuring that the die opening is smooth and well-aligned. Poor flow design can result in uneven extrusion, leading to weak spots or dimensional inconsistencies in the final product.

2. Heat Management and Cooling Efficiency

Another critical factor in die design is the management of heat throughout the extrusion process. Aluminum is a metal that reacts significantly to temperature changes, and controlling its temperature is crucial for maintaining the material’s workability and ensuring consistent results.

High-performance die designs often incorporate built-in cooling channels that help manage the temperature of the die during extrusion. Cooling channels allow for the controlled circulation of cooling fluids, which helps to prevent overheating, ensures uniform cooling of the aluminum material, and minimizes the risk of die wear. An efficient cooling system in the die design can also improve cycle times, making the process faster and more energy-efficient.

3. Die Material Selection

The material used for the die itself plays a major role in its performance.For example, some aluminum alloys may require a die material that can better resist corrosion, while others may need material with better thermal conductivity. Proper die material selection ensures longevity and reduces the chances of premature wear, deformation, or failure during the extrusion process.

4. Precision and Tolerance

Precision is at the heart of high-performance die design. A well-designed die must be able to produce aluminum profiles with tight tolerances, especially in industries where accuracy is essential. The die must be capable of delivering consistent results in terms of dimensions, shape, and surface finish.

Achieving high precision in die design requires careful engineering, with attention to detail in every aspect, from the geometry of the die cavity to the alignment of components. This ensures that the aluminum profile exiting the die matches the desired specifications within acceptable tolerances. Tight tolerances are especially critical in industries like aerospace, automotive, and electronics, where even the slightest dimensional errors can lead to significant performance issues.

5. Tooling and Maintenance Considerations

Another important aspect of high-performance die design is the ease of maintenance and tool changes. A good die design should incorporate features that make it easier to replace worn parts or perform repairs without disrupting the entire production process.

For example, die designs that include modular tooling or replaceable inserts allow manufacturers to quickly swap out parts that are subject to high wear. This minimizes downtime and keeps the extrusion process running smoothly. Additionally, ease of maintenance reduces the long-term costs associated with die wear and failure.

6. Cost-Effectiveness and Efficiency

While high-performance die designs focus on delivering top-quality results, they also need to be cost-effective. Manufacturers aim to strike a balance between die performance and production cost, ensuring that the die delivers consistent, high-quality aluminum extrusions without inflating production costs.

A well-designed die should minimize material waste, reduce energy consumption, and improve the overall speed of the extrusion process. Dies that are efficient in material flow and cooling will result in faster cycle times, which, in turn, lowers production costs. Additionally, dies that require less maintenance and have longer service lives contribute to overall cost savings over time.

Conclusion: Achieving High-Performance Die Design

A high-performance aluminum extrusion die design is essential for ensuring the success of the extrusion process. It combines several factors, including optimized material flow, efficient heat management, precise dimensions, durable materials, and cost-effectiveness. By focusing on these key areas, manufacturers can create aluminum products that meet the highest standards of quality and performance while improving the overall efficiency of the production process.

For those working in the aluminum extrusion industry, partnering with experts in software and die design tools can provide the right solutions for creating high-performance dies that optimize the entire process. As the demand for precision and efficiency in aluminum extrusion continues to grow, investing in top-tier die design will remain a critical factor for long-term success.

For more insightful articles related to this topic, feel free to visit mariatelkes.com